Introduction:

Hair straighteners have become an essential tool for many individuals striving for sleek, straight hair. But have you ever wondered how these tools are actually manufactured? From the initial design to the final packaging, the process of creating a hair straightener is both precise and intricate, involving advanced technologies and various techniques.Once the design is finalized, the production of key components like heating elements and housing materials begins. These parts are then carefully assembled into the finished product.

What Are the Key Materials Used in Manufacturing Hair Straighteners?

The performance of a hair straightener depends on the materials used, and Mesky prioritizes quality and safety when selecting them.

Heating Plates The most common materials for plates are ceramic, tourmaline, and titanium. Ceramic plates offer even heat distribution, minimizing damage to the hair.

Housing Hair straightener housings are usually made from plastic or metal. For premium models, metal housings are often used to increase strength and lifespan.

Electrical Components Each Mesky hair straightener features high-quality electrical components, including wiring and temperature control systems.

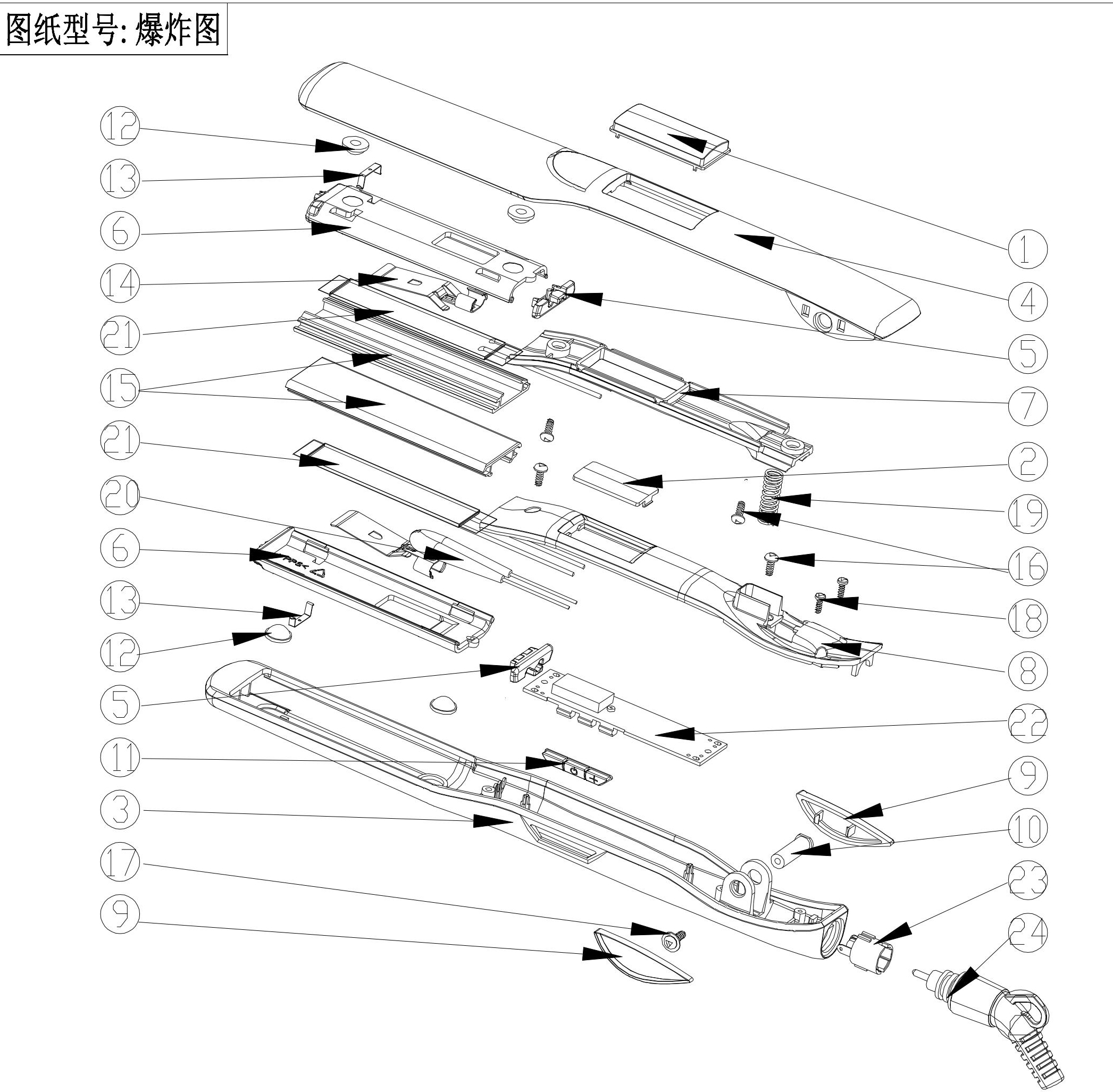

How Are Hair Straighteners Assembled?

Once all the parts are manufactured, they move on to the assembly stage. Mesky’s technicians assemble the heating plates, electrical components, and housing with precision. During the assembly process, each part is thoroughly inspected to ensure that all connections are secure and that electrical components are functioning correctly. Every Mesky hair straightener undergoes stringent assembly procedures to ensure that it delivers optimal performance every time it is used.

How Are Hair Straighteners Packaged and Distributed?

After passing through strict quality control, hair straighteners move into the packaging and distribution stages. At Mesky, we pay close attention to the packaging design of every straightener.

After packaging, the products are distributed through wholesale channels or e-commerce platforms to retailers and direct customers.

What is the Quality Control Process for Hair Straighteners?

1. High Voltage Testing

We subject every hair straightener to high voltage testing to ensure its electrical components remain stable under extreme voltage conditions. This test simulates electrical surges and ensures that the straightener does not experience electrical malfunctions or safety hazards like fires during normal usage.

2. Appearance Inspection

Appearance inspection is the first step to ensuring that the product looks aesthetically pleasing and is free from any functional defects. We carefully check the straightener’s casing, seams, and any potential cosmetic flaws such as scratches, cracks, or dents, guaranteeing the best visual appeal for consumers.

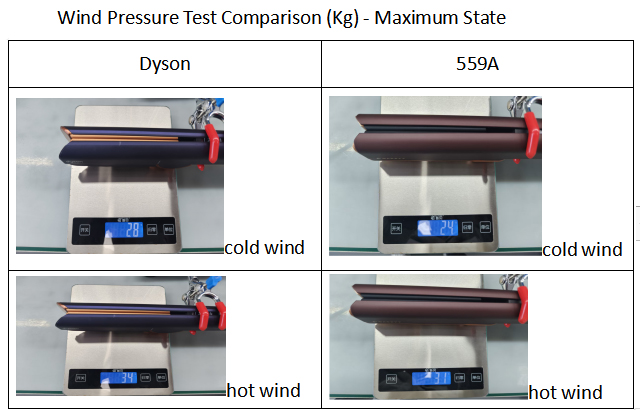

3. Functionality Testing

Functionality testing is one of the most crucial parts of hair straightener production. We conduct comprehensive tests on every straightener to ensure that all heating elements, electrical components, and control systems are working properly. We focus on the evenness of heat distribution, temperature regulation accuracy, and the sensitivity of the switches and controls.

4. Impact Testing

To simulate the impact the straightener may face during shipping, Mesky conducts impact testing to test the product’s shock resistance and durability. This process ensures that the hair straightener will not be physically damaged during transport, guaranteeing that the product reaches the customer in perfect condition.

5. Aging Test

The aging test helps us verify the long-term durability of the hair straightener. By simulating prolonged high-temperature usage, we can detect potential electrical issues, wear on heating plates, or component aging, ensuring the product’s lifespan meets the required standards.

6. Temperature Testing

Every hair straightener at Mesky undergoes rigorous temperature testing before leaving our factory. We check the accuracy of the temperature sensors and the stability of the heating elements to ensure that each unit heats up quickly, evenly, and maintains a consistent temperature throughout the styling process.

7. Simulated Transportation Vibration Testing

To ensure the straightener withstands transport without damage, Mesky performs simulated transportation vibration testing. We simulate various shipping environments and vibrations to test the structural integrity of the straightener, ensuring it can withstand potential shocks and vibrations during transit.

By conducting these comprehensive quality control tests, Mesky ensures that every hair straightener provides an exceptional user experience. We are committed to delivering only flawless, high-quality products that pass through our full range of testing procedures before reaching our customers.

What Innovations Are Shaping the Hair Straightener Industry?

Some of the most notable advancements include:

- Ionic technology: This helps to reduce static and frizz, leaving the hair smoother and shinier.

- Infrared technology: Infrared straighteners heat the hair from the inside out, which reduces heat damage and speeds up the straightening process.

- Smart features: Many modern straighteners come with advanced temperature sensors that adjust heat levels for optimal styling results.

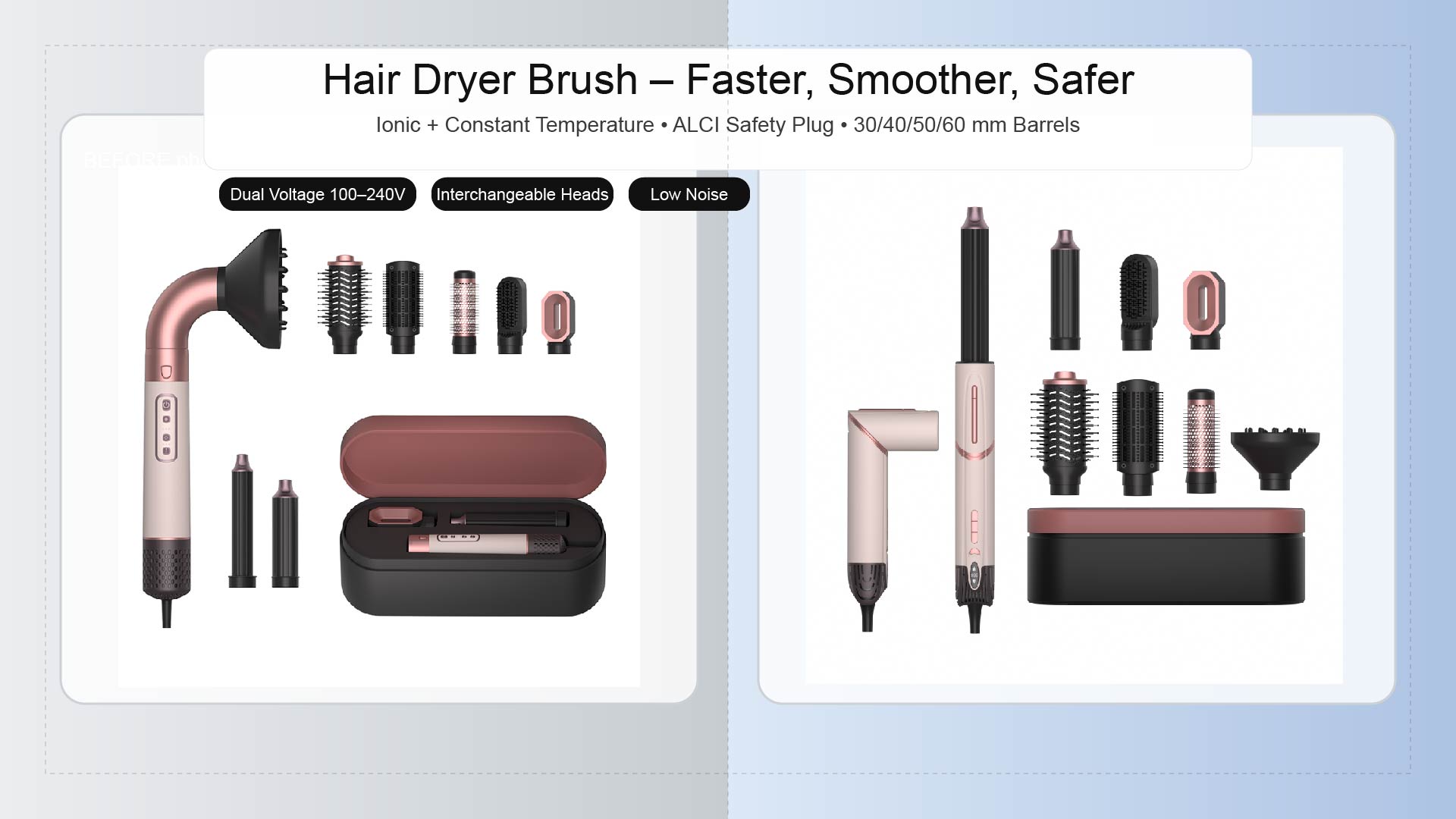

Mesky is Wet to Dry Hair Straightener wholesale manufacturer. it is the ideal product that combines cutting-edge technology, performance, and customer-centric features. we go beyond just providing top-quality products. We offer comprehensive after-sales support to ensure a smooth purchasing process for wholesale buyers and distributors:Quality Assurance and Free Returns,Free Product Images and Video Assets,Certification Support and Patent Protection

Conclusion: How to Learn More About Hair Straightener Manufacturing?

At this point, you should have a solid understanding of how hair straighteners are manufactured, from the initial design to the final distribution.Whether you are a wholesale retailer sourcing bulk products or a consumer interested in hair straightener technology, knowing the manufacturing process helps you make informed choices when selecting high-quality products.

Last Updated on 03/26/2025 by sales04