Third-Party Structural Evaluation Confirms Safety-Critical Design for North American Markets

Shenzhen, China | Official Release by MESKY

MESKY, a professional OEM and ODM hair dryer manufacturer, has recently completed a comprehensive product structure safety evaluation for one of its household hair dryer designs. Based on a mature engineering platform, the product structure was reviewed by Intertek Testing Services in accordance with the requirements of ANSI/UL 859 – Household Electric Personal Grooming Appliances, as well as the equivalent CSA C22.2 No.36 standard for Canada.

The evaluation resulted in a formal Constructional Data Report (CDR), confirming that the hair dryer’s internal construction and safety-critical design comply with applicable North American hair dryer safety standards and regulatory requirements.

Structural Safety Evaluation Based on UL 859 Requirements

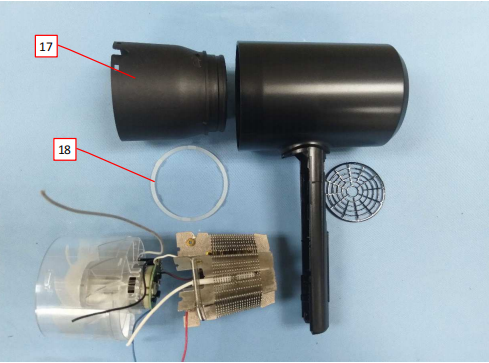

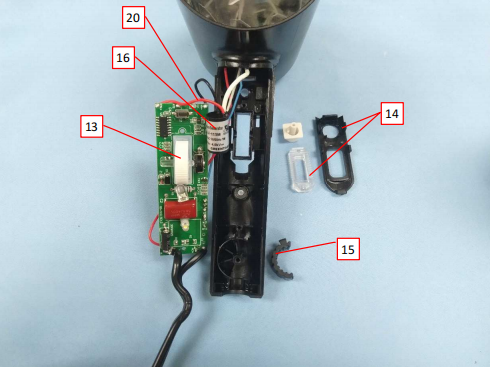

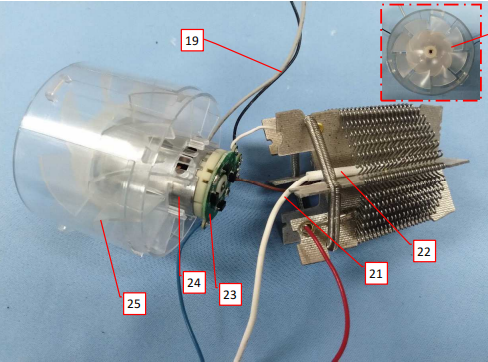

During the evaluation process, the hair dryer design was assessed from a structural and safety perspective, rather than surface appearance alone. The scope of review included a full internal examination of key systems, such as:

-

Heating system architecture and heating element construction

-

Motor assembly and airflow channel design

-

Main control PCB layout and electronic structure

-

Internal wiring routing, fixation, and insulation

-

Electrical and over-temperature protection mechanisms

-

ALCI (Appliance Leakage Circuit Interrupter) safety plug design

All structural assessments were conducted in accordance with UL 859 hair dryer compliance requirements and relevant CSA clauses, covering electrical safety, insulation spacing, material flammability, and mechanical integrity.

Safety-Critical Design Features Confirmed

The third-party evaluation confirms that the hair dryer design integrates multiple safety features required for products intended for the North American household market, including:

-

Integrated ALCI safety plug, reducing the risk of electric shock in bathroom and wet environments

-

Double-insulation construction, preventing access to live electrical parts

-

Thermal protection system, incorporating thermostats and thermal cutoff devices to prevent overheating

-

Controlled heating element design, with defined resistance values and compliant insulation spacing

-

UL-compliant internal wiring selection and routing, supporting long-term operational safety

These safety-critical elements form the foundation of a UL 859 compliant hair dryer design, suitable for regulated markets.

Component Selection and Manufacturing Consistency

From a manufacturing perspective, the evaluated design follows a compliance-oriented component selection strategy. Components directly related to electrical safety—such as power cords, switches, insulation materials, and protective devices—are specified in accordance with recognized certification requirements.

Where non-listed components are applied, they are evaluated under the structure-based provisions permitted by the applicable standards, ensuring suitability for their intended function and operating conditions. This approach supports production consistency and facilitates ongoing conformity during certification follow-up inspections and factory audits.

Supporting OEM / ODM Hair Dryer Projects

The reviewed hair dryer structure is suitable for OEM and ODM hair dryer manufacturing, supporting multiple models and brand configurations, provided that the core safety structure and critical components remain unchanged.

This compliance framework is widely adopted by international brand owners and distributors and helps reduce repeated certification risks while accelerating market entry for North America.

MESKY’s Commitment to Hair Dryer Safety and Compliance

As a manufacturer specializing in mid- to high-end hair care appliances, MESKY places strong emphasis on hair dryer safety compliance, structural reliability, and long-term manufacturing stability. Introducing third-party safety standards at the product design stage is a key part of MESKY’s compliance strategy for global markets.

MESKY will continue to enhance its engineering, testing, and regulatory compliance capabilities, providing reliable OEM hair dryer solutions for brand owners, distributors, and professional buyers worldwide.

About the Constructional Data Report (CDR)

A Constructional Data Report (CDR) is a technical document issued by an accredited third-party testing organization to verify that a product’s construction complies with applicable safety standards. It serves as a technical basis for certification assessment, factory inspections, and ongoing compliance management and is not intended as a consumer-facing certificate.

Last Updated on 12/19/2025 by sales04